How The US Army is Using Machine Learning Technology To Identify When Vehicles Need Maintenance And Repair

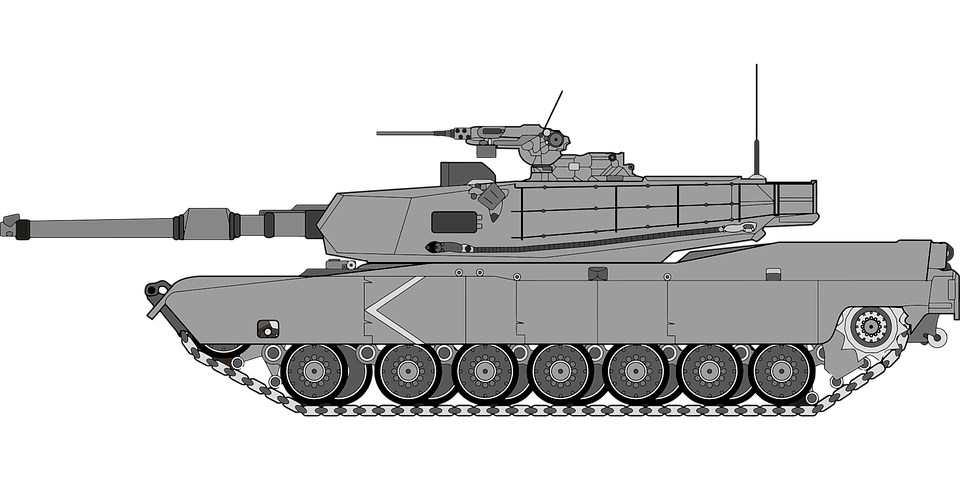

The US Army will work with Uptake to use machine learning software to predict when to maintain Bradley vehicle parts. Reduce the frequency of unscheduled repairs and improve maintenance efficiency through component failure prediction. Uptake is a company that specializes in artificial intelligence.

Tracking the mechanical health of millions of devices is a daunting task for the US military. To help with this data-intensive work, the US military is now planning to recruit an assistant. Machine learning software, developed by Chicago-based Uptake Technologies, will now be used to predict when vehicles need to be repaired and report problems to the US military before minor problems become catastrophes.

According to reports, the US Army will use machine learning software to predict when parts of Bradley combat vehicles need maintenance.

With an award from the Defense Innovation Experimental Unit (DIUx), the US Army will work with Uptake, Inc., which provides industrial intelligence solutions to customers in the industrial sector to predict failures of various components and reduce unscheduled maintenance. Improve the efficiency of maintenance operations.

“The Bradley combat vehicle has installed sensors on the main components of its system, so what we have to do is to acquire the data generated by the Bradley combat vehicle and then combine it with our software to predict Potential downtime,” said Uptake’s spokesperson Matthew Lehner.

Uptake’s software does not need to be loaded onto military vehicles, and the data acquired from the sensors is directly uploaded to the cloud, allowing analysis of normal operating modes and estimating potential hazards in the cloud.

“The company will also use its other industries that provide services to collect billions of hours of operational data,” Lehner said. “We have data on Bradley’s 230 million-hour diesel engine.”

Uptake’s interface monitors the combat vehicle. Once a fault is discovered, the system quickly lists the fault code and describes it to determine its severity (low, medium, severe) and the first and last occurrence of the fault. time.

This interface is largely consistent with standards within the industry, but the machine learning model needs to be changed before it is fully deployed and undergoes a verification process.

As early as 2016, the Logistics Support Agency of the US Army Equipment Command and IBM conducted a similar collaboration to use IBM’s Watson AI platform to help predict the maintenance support of Stryker.